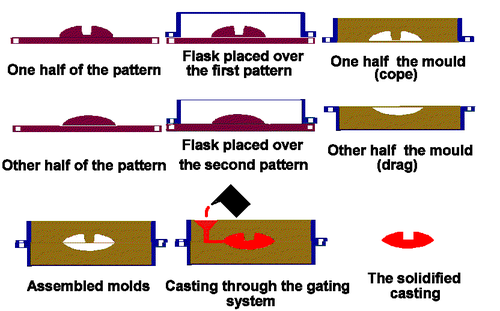

Zircon sand is a compound of approximately two-thirds zirconium oxide Zr 2 O and one-third silica. Oils, such as linseed oil , other vegetable oils and marine oils , used to be used as a binder, however due to their increasing cost, they have been mostly phased out. With a completed mold at the appropriate moisture content, the box containing the sand mold is then positioned for filling with molten metal—typically iron , steel , bronze , brass , aluminium , magnesium alloys, or various pot metal alloys, which often include lead , tin , and zinc.

Eric Lippert’s blog

If you notice a discrepancy between profits listed here and profits listed on guide pages, it is likely a caching issue. You can force this page to update by clicking. Do some research about the items first before you attempt to make money from. NOTE: Any method in the «Hourly Profit» section that relies on buying any item from the Grand Exchange is shown merely for the sake of completeness, as almost all of the shown methods involving purchases assume an infinite buy limit, which is unrealistic. Such methods include growing of saplings and processing of materials.

Account Options

Today another episode in my seldom-updated series about building a home aluminum foundry. Use a spray bottle set to a fine mist and stir the sand as you temper it. It should feel like perfect sand castle building material: wet enough to hold its shape but not so wet that you can squeeze water out of it. The pattern I am molding here is a one-piece pattern. I start by making a pattern out of wood and painting it with glossy spray paint so that damp sand will not stick to it.

The sand is typically contained in a system of frames or mold boxes known as a flask. Social Feeds. Receive updates via Reliance Foundry’s newsletter. The subsequent mold handling including turn-over, assembling, pushing-out on a conveyor were accomplished either manually or automatically. The Green Sand Process. With both methods, the sand mixture is packed around a patternforming a mold cavity. Additional sand is poured on the cope half until the pattern, core, and gating system are covered, and moneey the sand is compacted by vibration or mechanical means. Finally a cover is placed on the box and it is turned and unlatched, so that the halves of the mold may be parted and the pattern with its sprue and vent patterns removed.

Comments

Post a Comment